What is a filling line?

The filling line is a key part of most filling and packaging equipment, responsible for driving the production process. Its main function is to put the raw materials into the container, (edible oil filling machine factory china)and at the same time control the existing amount in the container to ensure the uniformity of the front and back, the quality assurance of the product and the cost saving.

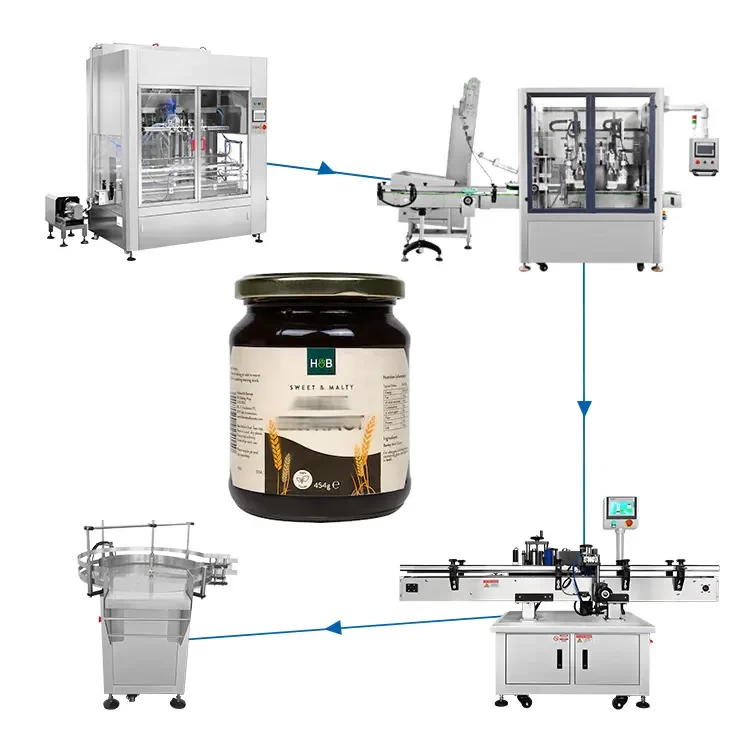

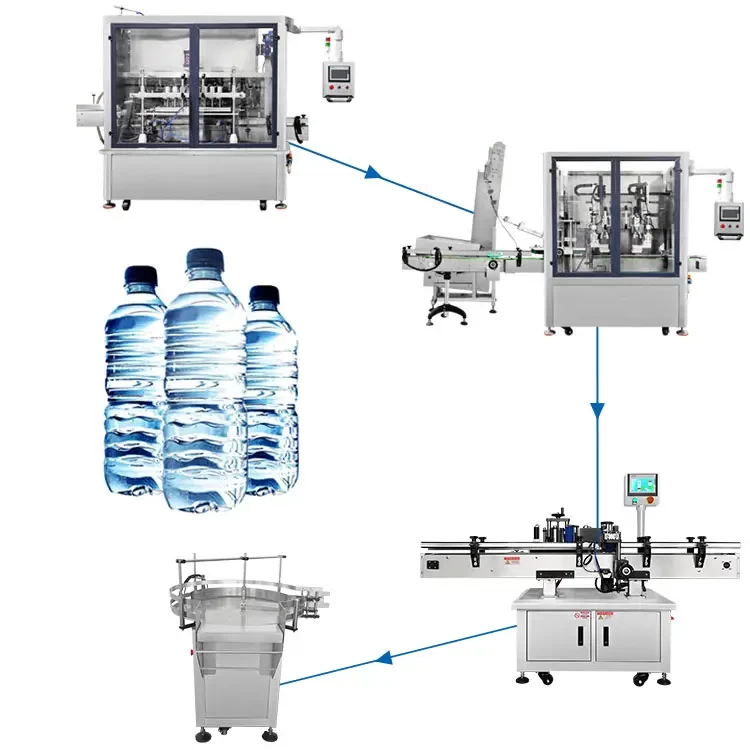

The filling line can be different according to the different products and containers.(sauce filling machine factory China) Filling equipment can be selected from low to high according to the size of the caliber and capacity, and there are also filling lines for special products such as water supply and oil. Generally speaking, the structure and characteristics of the filling line are changed due to product characteristics and production requirements.

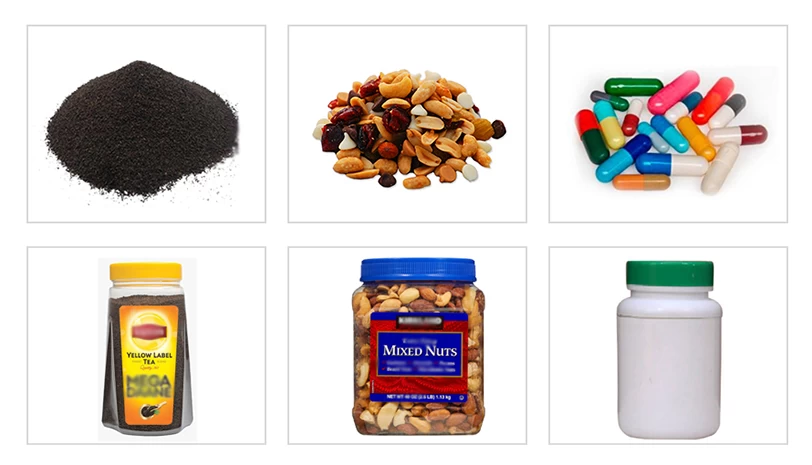

The equipment of the filling line can be divided into different types such as liquid, paste, and solid according to the characteristics of the product. These devices can be optimized, upgraded and modified in the design and manufacturing stages according to customer needs to improve production efficiency.

(tea bag filling machine manufacturer china)

The filling line has a wide range of applications. It can not only handle ordinary linear and L-shaped containers, but also complex multiple filling equipment, and can also meet the special requirements of containers and materials.

Generally speaking, the technical characteristics of the filling line include precision, production speed, secondary functions, sanitary equipment, safety automation equipment, and additions and improvements. In addition, the overall design of a filling line also needs to consider the interaction of the human-machine interface to improve the utilization rate of the equipment.

Generally speaking, the filling line is a very important part of the filling and packaging industry. It can provide stable and reliable guarantee for product quality, improve equipment utilization, thereby saving costs and achieving higher benefits.