Current status of development of tobacco packaging machinery technology in my country

There are many companies manufacturing tobacco packaging machinery in my country. Since 1988, it has introduced, digested and absorbed the packaging unit technology of companies such as Italian GD and German FOCKE, shortening the gap with foreign advanced levels, and the overall technical level has improved rapidly. Now it can provide 400 packs per minute ZB45 hard box packaging unit and ZB25 soft box packaging unit.

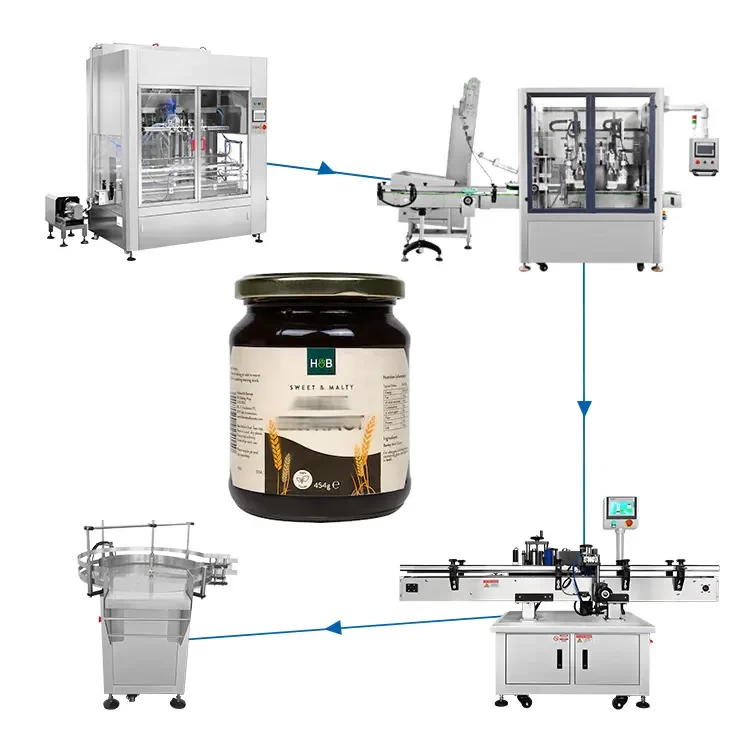

(China tobacco filling machine factory)

The above two models have the following advantages: high reliability; complete supporting facilities, strong versatility; complete functions, good real-time performance, friendly man-machine interface; intelligent system; powerful control software. Therefore, the possibility of flexible configuration of modules and hardware is improved, the self-diagnosis function of the equipment is increased, and the operating speed of the controller is accelerated.

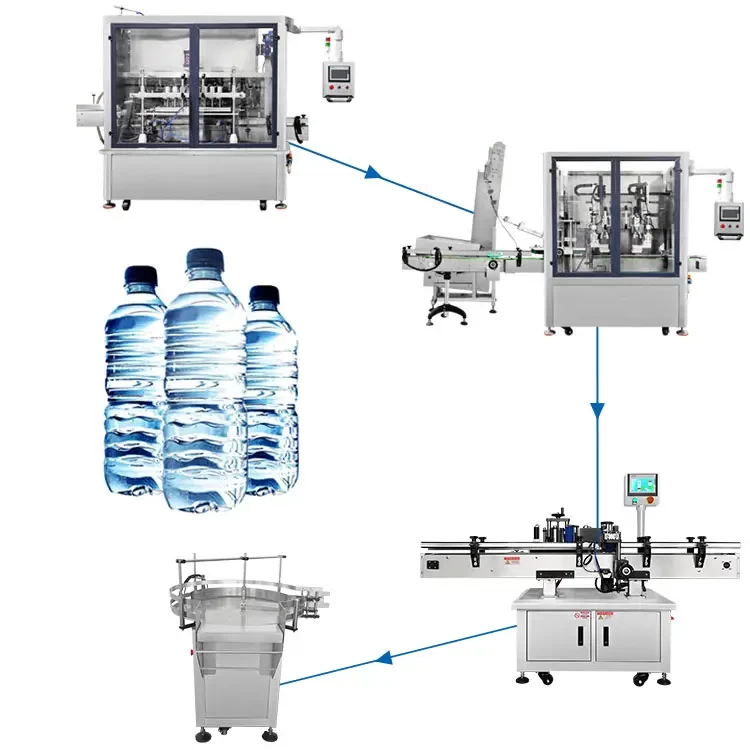

( tobacco packaging machine factory china)

Domestic research and development of ultra-high-speed packaging units has just started, and there is a certain gap with foreign countries. The rated production capacity of the ZB48 packaging machine is 800 bags/min. The control core is Beckhoff's IPC technology, that is, the embedded industrial control computer technology. The entire unit is controlled through industrial Ethernet, and a large number of Elau servo motors are used to simplify the mechanical structure and material detection. Visual inspection devices are widely used in general. IPC control has the advantages of fast calculation speed, high control precision, flexibility and changeability, and easy maintenance.

To sum up, ZB45 and ZB25 are still composed of the dedicated MICROII platform and dedicated circuit board developed by GD in the early stage in terms of the electrical control system of the whole machine. Compared with traditional PLC, they are more reliable and intelligent. With the development of microelectronics technology and the emergence of high-performance PLC and IPC, MICRO-II appears to have poor versatility and relatively backward technical level. The ZB45 and ZB25 systems adopt a proprietary bus structure, which is not conducive to system expansion and data collection, and does not meet the requirements of the information construction of various tobacco factories.

In terms of transmission system, there are still many DC frequency conversion and DC servo technologies. Due to the difficulty of DC frequency conversion and DC servo technology and the high cost of use and maintenance, the application market is gradually lost. Instead, AC frequency conversion technology and AC servo technology are used to control the operation of the motor.