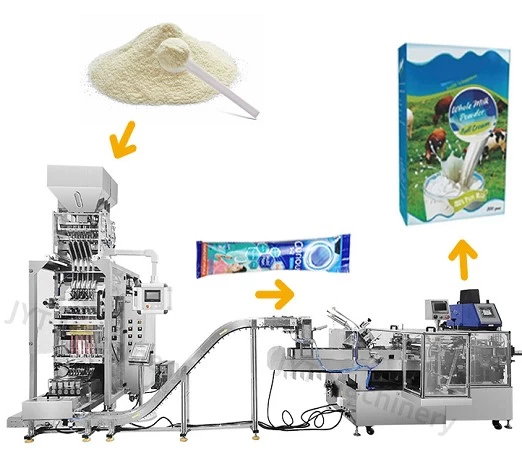

What is a multi-column powder packaging machine?

Multi-column powder packaging machine is a general term for packaging equipment for packaging powder products. There are many kinds of powder products, which can be involved in various industries such as industry, food, agricultural and sideline products, etc. It is suitable for powder products such as coffee powder, matcha powder, milk powder, coconut powder, chili powder, curry powder, corn flour, flour and so on.

(China Tea Powder Packaging Machine Supplier)

The automatic bagging machine for powder products can generally automatically complete all tasks such as metering, filling, sealing, and cutting. The measurement adopts the volume method, and some models are equipped with a reliable photoelectric detection system. When using the packaging material printed with the photoelectric logo, the complete logo pattern can be obtained. Powder packaging machine is suitable for small bag packaging in medicine, food, chemical, pesticide and other industries. It is suitable for manufacturers of powdered medicines, sugar, coffee(China coffee packing machine factory), fruit treasures, tea, monosodium glutamate, salt, seeds, desiccants and other powdered products.

The multi-column powder packaging machine produced by our company has the following characteristics

1. Automatically complete all tasks such as measurement, bag making, filling, sealing, batch number printing, slitting and counting.

2. Automatic slitting film system, multiple rows of bags are sealed at the same time.

3. Servo film feeding system, pneumatic control of horizontal sealing, accurate positioning, excellent performance and beautiful packaging.

4. The double light source photoelectric detection system is stable and reliable to ensure the integrity of the packaging bag.

5. Intelligent PLC control system, the machine runs stably, and the operation is convenient and fast.

6. A variety of automatic alarm protection functions can effectively reduce material loss and ensure work safety.

7. Use touch screen to set parameters and support multiple languages.