- Browse Categories

- Filling machine

- Tea packing machine series

- Packing machine

- Candy packing machine

- Screw packing machine

- Snus packing line

- Pillow packing machine

- Doypack bag packing machine

- Labeling machine

- Capping machine

- Shisha tobacco packing machine

- Other packing machine

- Cartoning machine series

- Hot products

- Most new products

- NewsMore>>

-

- Is the screw packaging machine easy to operate?

- The development direction of packaging machines in 2023

- Is the edible oil packaging machine easy to use?

- What are the measuring devices of packaging machinery?

- What is a filling line?

- Is the bread packaging machine easy to use?

- How to use the filling machine most efficiently

- The impact of new crown on automatic packaging machine equipment

- What is a coffee capsule packaging machine?

- What is the scented tea filling machine used for?

- Features of automation equipment

- Why is the price of the same packaging machine equipment very different?

- What is a sealer?

- Current status of development of tobacco packaging machinery technology in my country

- What is an automatic cable tie machine?

- Certifications

-

Easy to Operate Multi-function Back Sealing Bag Plastic Knife and Fork Packaging Machine

- The horizontal packaging machine is widely usded packaging machine. Suitable for packaging waffle snaps and other various products, includingmedical supplies, vegetables and meat toast, mooncake, candy, daily necessities, hardware accessories, etc.

Easy to Operate Multi-function Back Sealing Bag Plastic Knife and Fork Packaging Machine

Product Detail

Product Sample

Our Company

Product Description

Automatic suns packing plant requires you to only feed the cans,caps with tobacco, white snus,CBD,nicotine powder etc. The entire packing line is operated with the help of the following components.

The Snus packing line begins at the cap sorting unit, and it is designed to feed the caps along with a vertical layout. These caps are then transferred to the cap conveyor, which is connected to the Snus packing machine.

The snus packaging machine inserts the tobacco snus,white nicotine powder, CBD inside pouches according to the weight settings,and these pouches are packed inside cans.

An indexing table is used to input a defined number of pouches within each can. After the can is illed with pouches, the conveyor belt transfers it to the cap closing unit, where all the cans from multiple Snus packing machines are capped. Thus this section equals to a setup of automatic pouch packaging machines.

Next, they are sent to the labelling machines, which wrap the sealed cans with your brand labels, dates, and other information. Thus, at the end of the packaging line, you will get the finished product that is ready to be shipped.

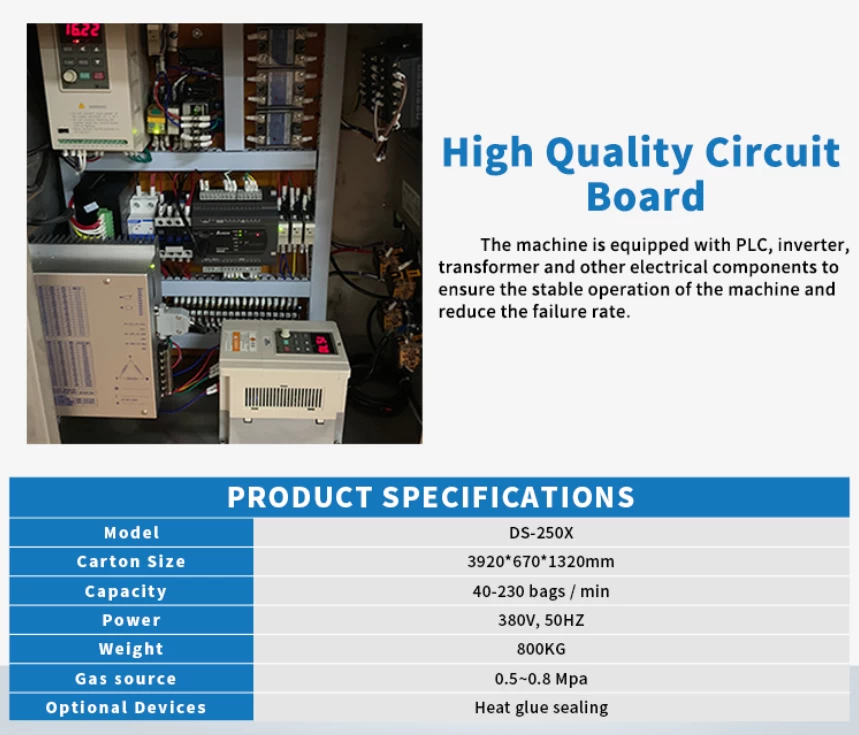

Product specification

| Model | JYT-250X |

| Film Width | Max 250mm |

| Bag length and width | L:45~190mm or 90-330mm; W:30-110mm |

| Product height | Max 40/70mm |

| Packing speed | 40-230bags/min |

| Motor Power | 220V,60 HZ,2.4KW |

| Machine Size | 3920*670*1320mm |

| Machine Weight | 420KG |

Payment

You can pay by 100% T/T, Ali-pay, 70% L/C at sight would be available for qualified bank.

Logistics

It can be shipped by terms of Ex-work, FCA,FOB,CNF,CIF by sea or by air DHL, UPS, FedEx, TNT, EMS etc,based on the buyer's forwarder or ours.

FAQ

Q1.Are you a manufacturer?

A1: Yes, we are an experienced manufacturer with our own brand and production lines.

Q2.How about quality of products?

A2: Our technicians and QC teams test the products one by one using aging line, professional devices and instruments to ensure the quality for all products.

Q3.How about price?

A3: We are a manufacturer and always offer our customers the most competitive prices.

Q4.How to place an order?

A4: Contact with online service, or sent email to us directly, we will reply to you with product price, specifications, packing etc. soon. Thank you.

Q5.May I send samples to you testing?

A5: Yes! You are welcome to send us your products to test by our machine.

Q6.Can I visit your factory?

A6: Yes, welcome to visit our factory at your convenient time.

Q7:What maintenance does the machine need?

A7:Naturally, to avoid machine problems, it is necessary to clean the machinery at the end of the production cycle.

Q8: How long does it take to change a film bobbon?

A8: The first times, when you are not already accomplished with the machine, it can take 5 or 6 minutes to change the film bobbin. After, when you have learned how to do it, it takes 1 and a half minute.

Tel:+86 13360354078

Wechat:+86 13360354078

Contact Person:Jenny Wu

PDF Show:PDF