- Browse Categories

- Filling machine

- Tea packing machine series

- Packing machine

- Candy packing machine

- Screw packing machine

- Snus packing line

- Pillow packing machine

- Doypack bag packing machine

- Labeling machine

- Capping machine

- Shisha tobacco packing machine

- Other packing machine

- Cartoning machine series

- Hot products

- Most new products

- NewsMore>>

-

- Is the screw packaging machine easy to operate?

- The development direction of packaging machines in 2023

- Is the edible oil packaging machine easy to use?

- What are the measuring devices of packaging machinery?

- What is a filling line?

- Is the bread packaging machine easy to use?

- How to use the filling machine most efficiently

- The impact of new crown on automatic packaging machine equipment

- What is a coffee capsule packaging machine?

- What is the scented tea filling machine used for?

- Features of automation equipment

- Why is the price of the same packaging machine equipment very different?

- What is a sealer?

- Current status of development of tobacco packaging machinery technology in my country

- What is an automatic cable tie machine?

- Certifications

-

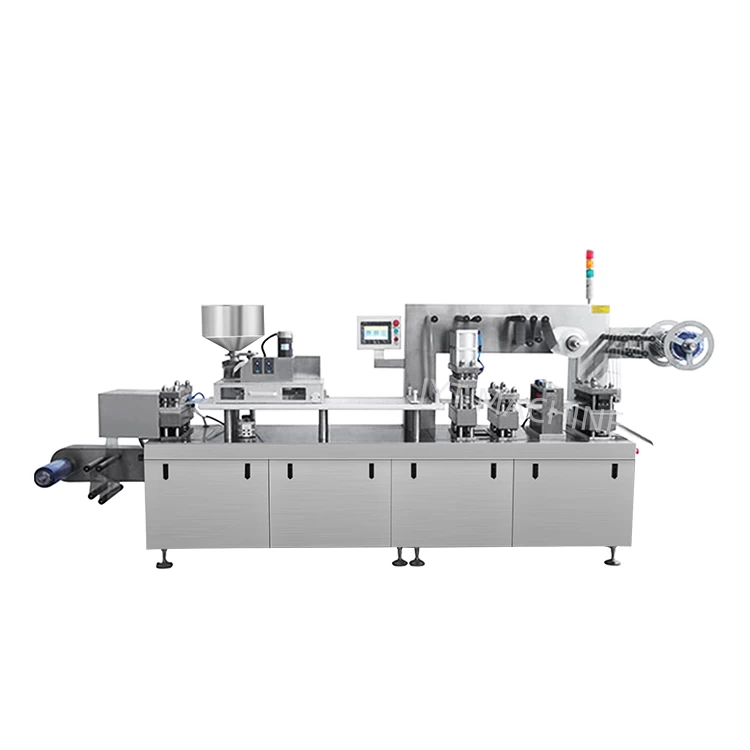

Fully automatic vitamin pill milk calcium tablet capsule blister pack packing machine

- The machine integrates ten functions such as coil uncoiling, aluminum-plastic feeding, blister forming, filling, waste recycling, heat sealing, batch number printing, mesh indentation, sheet blanking, finished product counting, etc. The finished product is well sealed and safe health.

Product Sample

Product Description

The machine is suitable for medicine, food, health care products, cosmetics and other industries, such as sugar-coated tablets, capsules, tablets, cod liver oil, milk tablets, candy, skin care lotion, jam, etc.

Product Advantages

Main Features

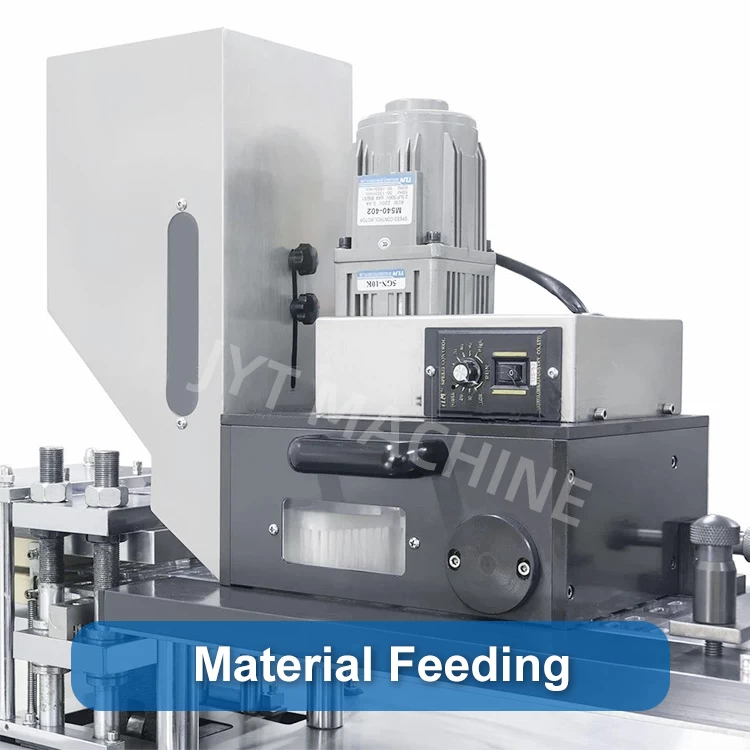

1.The machine can automatically complete film feeding, pressing, conveying, cutting, automatic shutdown and alarming.

2. It utilizes plate-type heating plate for heating. PVC sheets can be formed by positive pressure by heating to just about 105 ℃.

3. The frequency conversion stepless speed regulation is adopted, the punching speed is fast, and the adjustment is convenient.

4. It adopts the screw rod drive device. The packaging size of various sheets can be adjusted on the guide rail of the machine base at will.

5. The pneumatic roller traction device is controlled by PLC, with simple structure and accurate operation.

Product Specification

|

Model |

JYT-250 |

|

Cutting Frequency |

25-50 times/min |

|

Capacity |

6000-12000strip/hour |

|

Max shaping areas and depth |

300x120x20mm |

|

Air Pressure |

0.4-0.6Mpa |

|

Power Supply |

380V/220V 50Hz |

|

Voltage |

8.5kw |

|

PVC hard pieces |

0.25-0.5*250mm |

|

PTP Aluminum Foil |

0.02-0.035*250mm |

|

Dialysis Paper |

50-100g*250mm |

|

Mould Cooling |

tap water or back water |

|

Machine dimensions |

4000mm×760mm×1620mm |

|

Net weight |

1650Kg |

Payment

You can pay by 100% T/T, Ali-pay, 70% L/C at sight would be available for qualified bank.

Logistics

It can be shipped by terms of Ex-work, FCA,FOB,CNF,CIF by sea or by air DHL, UPS, FedEx, TNT, EMS etc,based on the buyer's forwarder or ours.

FAQ

Q1.Are you a manufacturer?

A1: Yes, we are an experienced manufacturer with our own brand and production lines.

Q2.How about quality of products?

A2: Our technicians and QC teams test the products one by one using aging line, professional devices and instruments to ensure the quality for all products.

Q3.How about price?

A3: We are a manufacturer and always offer our customers the most competitive prices.

Q4.How to place an order?

A4: Contact with online service, or sent email to us directly, we will reply to you with product price, specifications, packing etc. soon. Thank you.

Q5.May I send samples to you testing?

A5: Yes! You are welcome to send us your products to test by our machine.

Q6.Can I visit your factory?

A6: Yes, welcome to visit our factory at your convenient time(China automatic blister packaging machine factory).

Tel:+86 13360354078

Wechat:+86 13360354078

Contact Person:Jenny

PDF Show:PDF