How about the domestic market of liquid filling machines

With the continuous improvement of domestic social productivity and people's pursuit of a fast-paced lifestyle, (cbd oil filling machin china manufacturers)people's requirements for production efficiency are also constantly updated. Mechanized and automated production has gradually replaced the previous manual production.

(China Liquid Filling Sealing Machine Supplier)

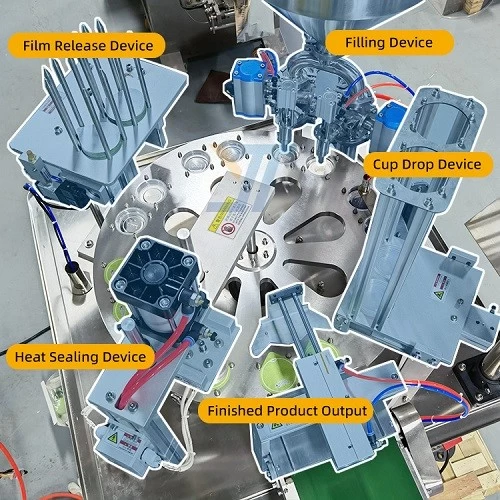

Liquid filling machines in the domestic market are usually divided into atmospheric filling machines, vacuum filling machines and pressure filling machines according to the filling principle. Under normal pressure, self-flow filling can be performed according to the weight of the liquid. The filling method, (China ice lolly packing machine supplier)Filling is carried out at a pressure higher than atmospheric pressure. The pressure in the liquid storage tank is higher than the pressure in the bottle. The beer liquid flows into the bottle by the pressure difference. The most important part of the filling machine is the PLC control system. Foshan Jiayite Machinery The liquid filling machine adopts PID temperature controller, and the temperature control is more accurate. Automatic cup drop is realized through PLC controller and various electrical accessories. Photoelectric eye tracking automatically corrects the alignment of the film pattern with the cup. The principle of the liquid filling machine is relatively simple. The modified control system greatly simplifies the complex mechanical structure. After on-site operation and control effect inspection, the degree of automation of the system meets the design requirements, which greatly reduces the labor of operators. Strength, so that the daily output of liquid filling is more than 30% higher than in the past, and the failure rate is greatly reduced.

This reflects the automatic control technology of modern equipment. It is innovated on the basis of digesting and absorbing the advanced technical principles of today's industrial control, and developed the most advanced filling control system in China.

The needs of liquid filling machines are not only to meet the needs of the market but also to meet the needs of people. In fact, to be honest, the needs of users are the needs of the market, and their needs determine the direction of the development of the filling machine industry. Now with the seasonal changes, the market demand for filling machines is extremely rising, and it is better reflected in the use of the beverage industry. The current filling machines use stainless steel body material and high-end technology supporting facilities. Now it has developed into a liquid filling production line, and the production efficiency has been greatly improved.

The development of the market regards the use of liquid filling machines as very important. Due to the continuous improvement of consumer demand, the requirements for technological innovation of filling machines are also increasing. For production enterprises, the development direction of the enterprise must be directed towards The direction of market development is in line with the direction of user needs, and continuous technological innovation is carried out according to customer needs to strive for better and higher brands.