How to choose the equipment of the cartoning machine?

A good carton packaging machine can not only greatly improve the company's production capacity, but also save labor costs, so the following points need to be considered when choosing packaging machine equipment.

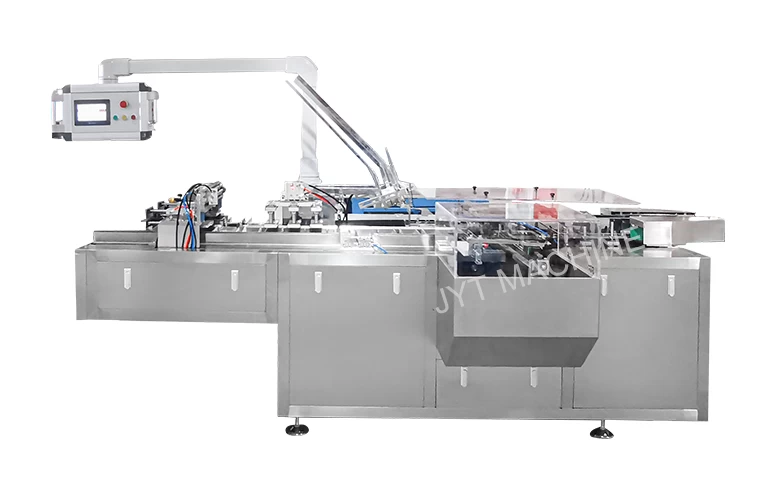

China cartoning machine factory

1. It depends on whether your product conforms to horizontal or vertical packaging.

In fact, the cartoner you choose needs to match your product. For example, if the product is free-flowing (granular objects like laundry detergent or loose objects like cough syrup bottles), you should choose a vertical cartoner. For products that can be loaded vertically and horizontally, it is best to choose a horizontal cartoner. Most cartoners on the market are horizontal, which is more flexible and less expensive than vertical cartoners.

2. You need to consider your speed requirements for the cartoning machine.

The first is to determine whether your product requires an online or offline production line. For line speed, divide the product's maximum production speed by the number of packs per case, and then consider overload capacity (the possibility of increasing production speed through a new process or technology). For offline speed, determine your daily, weekly or monthly shipping quota and be sure to use the actual number of days per week or hours per day to calculate how many cartons can be loaded per minute.

3. Material issues that need to be considered.

The cartoning machine is relatively uncomplicated. Many cartoning machine problems are actually material problems, so the choice of materials is very important. In order to improve reliability, the high quality of the materials must be guaranteed. Are you using virgin cardboard (new fiber, more expensive) or recycled material (cheaper)? Inferior materials will inevitably affect the packaging quality. You should also consider the design of carton covers and adhesive formats. Less glue can be used if a stitched format is used. When you put a bag into a carton, the air creates a material shock. A pressure reducer can be installed on the bag making machine, or a bag gauge can be installed in the feeding area of the bag making machine to reduce the impact force. Both methods are possible, but you need to prepare ahead of time rather than ship the equipment to the site to fix the problem. You can test the boxing effect of the cartoner with products and cartons that meet specifications to know how much air can hold in the bag.

4. We should make full use of the experience and knowledge of equipment suppliers.

Include your carton supplier on your project team. You will benefit greatly from bringing together materials experts and equipment experts. Sometimes small changes in carton design, materials and coatings can greatly improve carton performance. Sometimes, if the equipment supplier can specifically design the equipment, you may be able to optimize the carton design and use thinner material to save costs.

5. The optional packaging machine should meet your technical ability.

The carton packaging machine must match the technical strength of your company. If the company's technology isn't hard enough, opting for a more sophisticated cartoner can pose a lot of problems. All manufacturers who buy packaging machines should carefully understand the manufacturers and consult technical personnel. However, it is not something that your company can solve to determine whether the equipment you choose meets your specifications. At the same time, make sure your product and the manufacturer's technology are within the limits of the device.

The above is the selection and analysis content of the cartoning machine. If you have any other questions, feel free to contact us.