Is Powder Filling Machine Worth Buying?

The powder filling machine is an economical and applicable automatic filling machine for powder and small particles, which can complete the automatic positioning, filling and measuring of bottles. The automatic milk powder filling machine consists of a filling head, a chain conveyor belt and a It is composed of positioning device. The automatic powder filling machine adopts servo (or stepping) motor, PLC and touch screen control, which is easy to operate and has high stability. It can be combined with bottle unscrambler, capping machine, labeling machine, etc. to form a complete filling line. The cost of such equipment is not cheap, and the selling price must be extremely high. Many manufacturers have purchased inferior powder filling machines before. , the impact on manufacturers and equipment is greatly reduced, in fact, it is not, let's take a look at this device together.

Product Usage

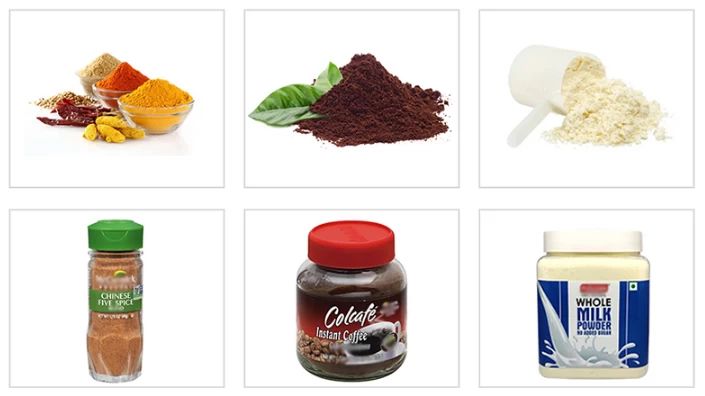

It is suitable for quantitative packaging of powder materials in the food, pharmaceutical, biological, chemical and other industries, such as medicine, milk powder, soy milk, health food, seasoning, facial mask powder, animal medicine (powder), etc.

The editor will analyze why the powder packaging machine has great development potential in the future from the scope of application, the composition material and the benefits it brings to people.

Application scope of powder filling machine

Powder filling machine (detergent powder filling machine suppliler)is suitable for packaging powder and small granular materials, such as powder, small granule medicines, veterinary drugs, glucose, condiments, solid beverages, toner, talcum powder, pesticides, etc.

The features of powder filling machine are as follows

1. PLC control system, user-friendly design, high degree of automation, fault self-alarm, self-stop, self-diagnosis, safe and simple use, and fast maintenance.

2. Automatically complete all the work of measuring, bag making, filling, sealing, cutting, counting and so on.

3. Modular design of the whole machine, strong versatility, can achieve the purpose of multi-purpose by changing different metering devices, saving valuable factory investment.

4. The stepper motion control system is used to control the bag pulling, with high precision, and the length of the bag can be changed without changing parts.

5. Adjusting the stepless speed regulating mechanism within the rated range can realize the control of the bag pulling speed.

6. Using the advanced cursor tracking system, when packing color-coded packaging materials, a complete trademark pattern can be obtained.

7. High-quality stainless steel is used in contact with materials to ensure that the materials are not polluted during the work process, the machine is easy to clean, and meets the requirements of GMP for pharmaceuticals and QS for food quality and safety certification.

8. The electrical control part adopts well-known brand electrical components and stepping control system to ensure the stable operation of the machine and realize mass production with high efficiency and low failure.

Foshan Jiayite Automation Equipment Co., Ltd. has always had a good market reputation in the filling equipment industry. The quality of the powder filling machines we produce has been strictly controlled and repeatedly debugged. Jiayite sincerely hopes that everyone Customers can buy their favorite filling machines here. Here, I hope to have the opportunity to cooperate with you.