What are the characteristics of automatic pillow packaging machine?

Automatic pillow packaging machines are frequently used in packaging machines, so what are the characteristics of automatic pillow packaging machines? Next, the automatic pillow packaging machine manufacturer will introduce the characteristics of the automatic pillow packaging machine to you. Follow this article to find out.

The machine has the function of automatically adjusting the packaging length according to the length of the product, and can be used for packaging products of different sizes and shapes.

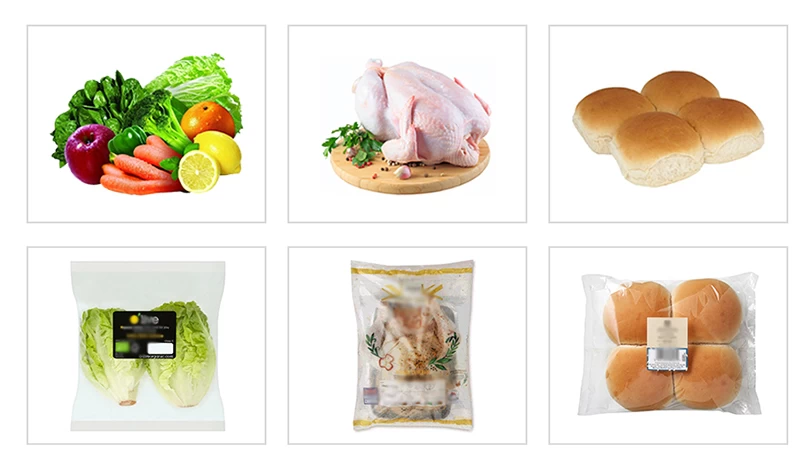

Suitable for vegetables, fruits, cucumbers, cabbage, carrots, cauliflower, bitter beans, peppers, green beans, mushrooms, onions, peas, potatoes, squash. Tapioca, Tomato, Salad Leaf, Onion, Chicken Thigh, Lemon, Banana, Apple, Orange, Grape, Papaya, Mango, Pineapple.

Main performance and features:

1.3-axis servo drive system: The end sealing unit, film feeding and feeding chain are all independently driven by servo motors.

2. Humanized man-machine interface control, 7.4-inch color display.

3. The bag length, slitting and feeding are independently controlled, and the production conversion is convenient and fast.

4. Servo drive control, accurate bag length.

5. The feeding position parameters are set and saved through the touch screen, and automatically positioned when the production is switched.

6. The drive transmission parts are largely eliminated, which greatly reduces noise, vibration, maintenance, and improves the accuracy and operation ability.

Fruits Vegetable Packing Machine

Precautions:

1. When the temperature is too high, the speed is too slow, and the heat resistance of the outer layer of the coating is poor, there will be traces of scorch wrinkles on the seal. The repair method is to increase the speed, reduce the temperature, and replace the film material.

2. The knife seat is too high or too low, the packaging speed is too fast, and when the push rod and the cutter are not synchronized, the cutter will cut on the product. The maintenance method is to reduce the packaging speed and adjust the height of the end sealing parts, so that the center of the sealing knife is at the center of the product. The middle position of the product height

3. The color of the film color code is too light, the film drive is slippery, and the cutting position will deviate from the color code when the color code tracking is not turned on. At this time, the maintenance method is to refer to the packaging machine manual and adjust its sensitivity; in the man-machine dialogue interface, Switch the tracking mode to "Track Cut"

4. The solid-state circuit breaker is burned out, the temperature control meter is damaged, and the thermometer cannot control the temperature when the thermocouple is damaged. The maintenance method is to replace the galvanic couple, replace the temperature control meter, and replace the heating element

5. If the speed is too fast, the inner layer of the film has poor heat-sealing properties. When the temperature is too low, the seal will leak or be unstable. The maintenance method is to slow down the speed, increase the temperature, and replace the material of the film.

6. The air pressure is wrong, the cylinder swing rod is loose, the heating temperature is low, and the heat seal is not good when the hot pressing roller and the transmission roller are not parallel. The maintenance method is to adjust the parallelism, adjust the temperature and air pressure to tighten it.

shisha packing machine on sale

What are the characteristics of the automatic pillow packaging machine? The characteristics of the automatic pillow packaging machine are introduced here, I hope it will be helpful to you