Maintenance of feed bag packaging machine

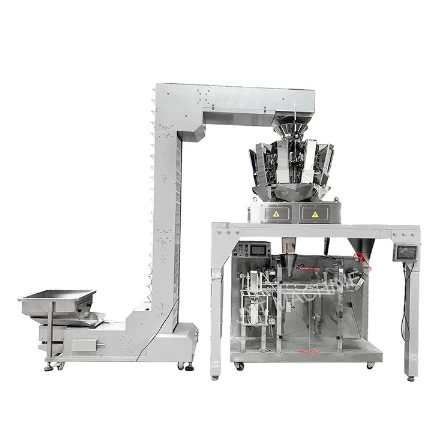

Bag feeding and packaging machine plays an important role in our life. It is applicable to the packaging of various granular products, such as crystal monosodium glutamate, granular medicine, capsules, seeds, chemicals, sugar, chicken essence, melon seeds, nuts, pesticides and fertilizers. How is it maintained?

1. The automatic bag feeding food packaging machine(nuts automatic packing machine china factory) shall be selected in the natural environment of - 10 ℃ - 50 ℃ and the extreme ambient humidity is not less than 85%. The relative humidity of the air will damage the electrical components of the machine and reduce the service life of the machine and equipment.

2. When refitting the automatic bag feeding food packaging machine, attention shall be paid to the reliable grounding system. The power plug of the machine shall be connected with the knife switch or the leakage protection switch as much as possible. It is not necessary to select the power socket to prevent the production workshop from drying, safety accidents and damage of machinery and equipment.

3. When selecting the bag feeding food packaging machine, (washing powder packing machine china)the professional and technical personnel shall be properly trained. After the machine and equipment are completed and put into operation, the professional and technical personnel of the automatic control system will adjust and change the machine and equipment without training. If the manual type is not good, it may cause the machine equipment to be unable to run and the automatic control system to be unstable.

4. In order to ensure the stable operation of the mechanical pump of the food packaging machine, the oil quantity should be frequently detected. The stable oil volume shall be 2 / 3 of the oil level. When there is ice in the mechanical pump or the oil is afraid of black, the oil polluted by the environment shall be drained and new oil shall be added (generally, the oil shall be removed and replaced once every three months, and the special oil for the mechanical pump is required, which will cause great damage to the mechanical pump and short application period).

5. Add lubricating grease to the mechanical equipment of the machinery and equipment, and drive steadily for 90 days, so as to ensure that the machinery and equipment can be used for internship.

6. Disinfect and sterilize the machinery and equipment at the end of each day to prevent the remaining objects in the machinery and equipment from fading into the weathering layer, which is more in line with the provisions of food hygiene and safety.

7. Before and after the daily operation of the vacuum packaging machine for bagged food, check whether there is residue on the protective cloth and whether it is flat to ensure the sealing quality of the machine and equipment. The relevant contents of the automatic bag feeding food vacuum packaging machine seem boring, but it will have a particularly important effect on the professional and technical personnel of our factory。

In order to better improve the workload, the food industrial production company has provided the molding operation procedures when designing the scheme machinery and equipment, which is convenient for operators to quickly start and complete the operation steps, saving costs for the production enterprises and improving production efficiency.