How bread is packaged

Currently, about 90% of bread is packaged in polyethylene plastic bags. Its advantages are that it can be used repeatedly, it is easy to pick up the bread, and the shelf life is long, and the surface does not need to be bundled. Packaged bread. What is more particular is the use of aluminum foil/composite material or polyethylene composite material or aluminum foil/polyethylene composite material. Although this type of packaging material is opaque, it can protect the vitamin B1 in the bread from loss.

What is the role of bread packaging?

1. Keep the bread clean and hygienic to avoid contamination during storage, transportation and sales.

2. Prevent the bread from hardening and prolong the shelf life. Bread needs to be stored and transported for a period of time from the factory to the consumer. Due to the aging of starch and evaporation of water, the bread will become hard and lose its soft and palatable characteristics. After the bread is packaged, it can avoid a lot of moisture loss and maintain the freshness of the bread. The moisture content of bread should be kept at 35%-40%.

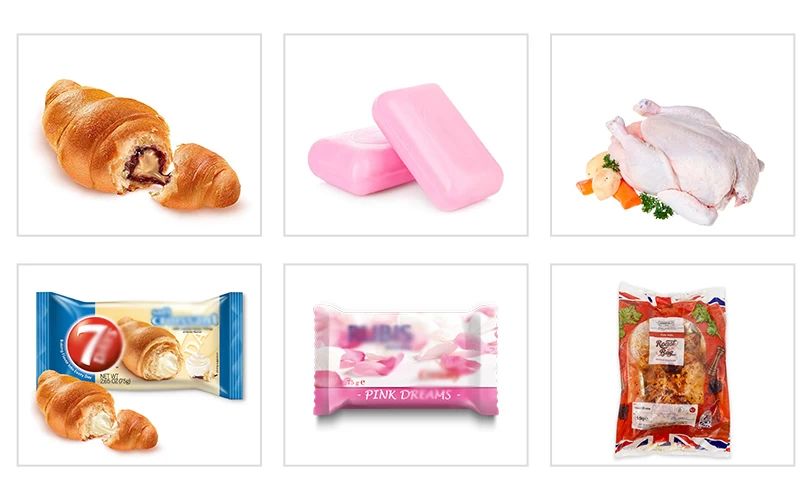

3. Increase the beauty of the product. Generous and beautiful packaging can attract consumers' attention, highlight product features, and expand consumption.

Then, what should be paid attention to in the packaging method and packaging material requirements?

Packaging method: The packaging methods include manual packaging, semi-mechanical packaging and automatic packaging (bread packaging machine wholesale China). Manual packaging is less restricted by factors such as capital, site, and product quantity, and is more flexible to use. Semi-mechanized and automatic packaging are all packaged by packaging machines.

Requirements for packaging materials:

1. It must meet the requirements of food hygiene, non-toxic, odorless, tasteless, and will not directly or indirectly pollute the bread.

2. Good airtight performance, watertight and airtight as much as possible, so as not to dry and harden the bread and lose the fragrance.

3. For mechanical packaging, the packaging material should preferably have certain mechanical properties to facilitate mechanical operation and protect the bread from mechanical damage.

4. The price is suitable, and the packaging quality can be improved as much as possible within a certain cost range.

The commonly used packaging materials for bread are divided into paper and plastic. Papers include oil-resistant paper, wax paper, etc.; plastics include nitrocellulose film, polyethylene, polypropylene, etc.

There are many types of packaging machines, which are divided into folding packaging, shrink packaging, bag packaging and so on according to the packaging form.

The suitable relative humidity of the bread packaging room is preferably 75%-80%, because too drying will cause the film to shrink; the temperature is preferably 22-26 degrees, because the high temperature will cause adhesion and affect the transportation of packaging materials. Bread cooled to 28-38 degrees is best for packaging.